Introduction

NODA Intelligent Systems (NODA) is a spin-off company from research within artificial intelligence at Blekinge Institute of Technology, Sweden. NODA was founded in 2005 and currently has offices in Karlshamn and Malmö in Sweden.

NODA has customers and partners throughout Europe, North America and Asia. The focus of NODA is to develop and market AI-based solutions for thermal systems like district heating and cooling, heat pumps and gas.

In addition, NODA has a strong relationship with universities and research institutes in research and innovation. NODA works with several partners and customers to implement its technology and market approach. These partners range from large global companies to local and regional energy companies or building owners.

Traditionally, the focus of NODA has primarily been on district heating. Still, the last few years have seen an increased focus on hybrid systems based on thermal processes such as combined heat and power, heat pumps and excess heat extraction. This gives NODA a broad range of working knowledge of different types of systems and how they can be combined.

NODA works in the production and delivery chain regarding product development from core research to operational products and routinely participates in international and national research and innovation projects.

Products and services

NODA works with a wide variety of partners and we implement hardware or software integrations wherever needed. In addition, by avoiding tying oneself to a particular equipment manufacturer and relying on in-house software development, NODA is flexible enough to change when new requirements call for change.

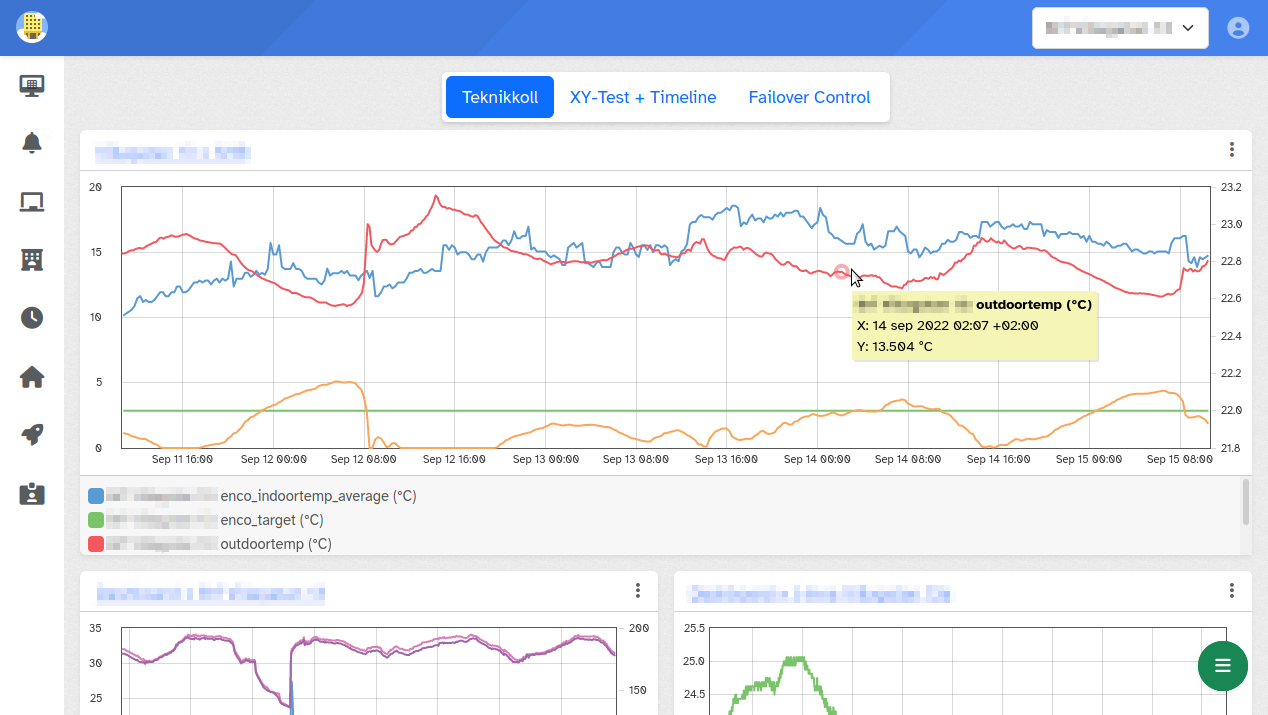

EnergyView

This tool has evolved over the years. Its inception was back in 2009 under the working name Linckii. EnergyView is the primary tool for interacting with data stored from communication with field equipment and the output from our machine learning algorithms.

We deploy each customer domain on a separate database. Thus, creating partitions between customers to prevent accidental, unauthorized access.

EnergyView allows access to the time-series data through configurable time-series graphs. Users with more than basic access privileges can change most aspects of an installation.

The system also exposes essential objects as a REST API over HTTP. This interface allows for third-party interaction with the system.

My Pages

My Pages is a much simpler tool compared to EnergyView. Its demographic is customers who want a direct answer, not a philosophical discussion surrounding the question.

Here customers can see all control actions the NODA equipment has performed. They can also get an energy analysis of their heating system and energy consumption along with time-series graphs of their indoor sensors.

Self-host

The purpose of the NODA Self-host is to provide customers with an option to run the core components of the NODA system in their environment as their responsibility. This includes;

- API Server (Aapije)

- Program Server (Juvuln and Malgomaj)

- DBMS (PostgreSQL 12.0+)

These components are all Open Source and freely available for anyone to use without paying for the software. However, a negotiated support agreement is required for aid in deployment.

In a project, we expect customer-specific integrations and the addition of NODAs proprietary software.

Components such as;

- Machine Learning Algorithms (Kimaera)

- MQTT protocol translation bridges

- User interfaces

Document Notes

All information in this manual, including product data, diagrams, charts, etcetera. represents information on products at the time of publication, and is subject to change without prior notice due to product improvements or other reasons.

The documentation and product are provided on an "as is" basis only and may contain deficiencies or inadequacies. NODA Intelligent Systems AB takes no responsibility for damages, liabilities or other losses by using this product.

Copyright and trademark

© 2024, NODA Intelligent Systems AB.

All rights reserved. No part of the contents of this manual may be transmitted or reproduced in any form by any means without the written permission of NODA Intelligent Systems AB.

Contact information

NODA Intelligent Systems AB Headquarter

Biblioteksgatan 4

374 35 Karlshamn

SWEDEN

- 📞 Phone: +46 454 10 271

- 📧 E-Mail: info@noda.se

NODA Intelligent Systems AB Technical Support

- 📞 Phone: +46 454 10 271

- 📧 E-Mail: support@noda.se

- 🌎 Online: https://www.noda.se

NODA Glossary

This is a glossary of terms used in the NODA documentation.

District heating terminology

| Term | Definition |

|---|---|

| CHP | Combined heat and power, also known as cogeneration, is a system that generates both electricity and heat from a single fuel source, such as natural gas, biomass, or biogas. CHP systems can be more efficient and environmentally friendly than traditional power generation and heating systems. |

| District heating | A system that delivers heat from a central source, such as a CHP plant or a heating plant, to multiple buildings or homes through a network of underground pipes. District heating systems can be more efficient and environmentally friendly than individual heating systems in each building. |

| Heat exchanger | A device that transfers heat from one fluid or medium to another, without the two fluids or media coming into direct contact. Heat exchangers are commonly used in district heating systems to transfer heat from the hot water in the pipes to the water in the building's heating system. |

| Heat meter | A device that measures the amount of heat delivered to a building or home through a district heating system. Heat meters are typically used to bill customers for the heat they consume based on their usage. |

| Heat network | Another term for a district heating system, referring to the network of pipes that delivers heat from a central source to multiple buildings or homes. |

| Pipe insulation | Insulation that is used to wrap the pipes in a district heating system to reduce heat loss and improve efficiency. |

| Primary loop | The portion of a district heating system that carries hot water from the central source, such as a CHP plant or a heating plant, to the substations. |

| Secondary loop | The portion of a district heating system that carries hot water from the substations to the buildings or homes. |

| Substation | A device that is used to control and distribute the heat delivered by a district heating system to multiple buildings or homes. A substation typically includes a heat exchanger, a pump, and other equipment to regulate the flow of heat and maintain the desired temperature in the heating system. |

| Temperature control valve | A valve that is used to regulate the flow of hot water in a district heating system and maintain the desired temperature in the heating system. |

| Thermal storage | The use of heat storage tanks or other devices to store excess heat generated by a district heating system for later use. Thermal storage can help to smooth out fluctuations in |

IT-infrastructure

| Term | Definition |

|---|---|

| Backup | The process of creating copies of data or other resources in case the original is lost, damaged, or otherwise becomes unavailable. Backups are typically stored on separate devices or media, such as external hard drives or cloud storage, to ensure that they are not lost along with the original. |

| Cloud computing | A model of computing in which users access and use shared resources, such as computing power, storage, and software, over the internet, rather than using their own local resources. Cloud computing can be more cost-effective and scalable than traditional computing models. |

| Data center | A facility that houses and supports the operation of servers, storage systems, and other IT infrastructure. Data centers may be owned and operated by a company, or they may be provided by a third party as a service. |

| Domain name | A unique name that is used to identify a website or other internet resource. Domain names are typically organized into a hierarchy based on the type of resource, such as .com for commercial websites, .gov for US government websites, and .edu for educational websites. |

| Firewall | A security system that monitors and controls incoming and outgoing network traffic based on predetermined security rules. Firewalls are used to protect networks from unauthorized access, malware, and other threats. |

| Infrastructure | The underlying framework or structures that support the operation of a system or service. In the context of IT, infrastructure typically refers to the hardware, software, and other resources that are needed to support the operation of a network or other IT system. |

| Load balancer | A device or software that distributes incoming network traffic across multiple servers or resources to improve the performance and availability of a network or service. Load balancers can use various algorithms to determine how to route traffic, such as round-robin or least connections. |

| Managed service | A service provided by a third party that is responsible for the management and maintenance of a particular aspect of an organization's IT infrastructure, such as security, storage, or networking. Managed services can help organizations to more effectively manage their IT resources and reduce costs. |

| Network segment | A portion of a network that is separated from other parts of the network by a device, such as a switch or router. Network segments can be used to improve the performance and security of a network by isolating traffic and limiting access to certain resources. |

| Protocol | A set of rules or conventions that govern the communication between devices or systems. Protocols define how devices should connect, transmit data, and handle errors. There are many different protocols used in networking and other fields, such as HTTP, SMTP, and FTP. |

| Router | A device that connects multiple networks and forwards data packets between them based on their destination. Routers use routing tables and protocols to determine the most efficient path for data to travel and can also provide security and other networking services. |

| Security group | A collection of rules that define the traffic that is allowed to flow in and out of a network or resource. Security groups can be used to control access to resources and protect them from unauthorized access or attacks. |

| Virtual machine | A software-based simulation of a physical computer that runs on top of a host operating system. Virtual machines allow multiple operating systems or applications to run on a single physical server, providing benefits such as improved resource utilization and easier management. |

| Virtual network | A network that is created and managed entirely within software, rather than using physical networking hardware. Virtual networks can be used to create isolated networking environments within a larger network, or to connect multiple networks together. |

| Virtual private network (VPN) | A private network that is created over a public network, such as the internet. VPNs use encryption and other security measures to protect data transmitted over the network and to provide secure remote access to resources. |

| VLAN | A virtual local area network (VLAN) is a logical grouping of devices that are created within a larger network. VLANs are used to segment a network into smaller, more secure and efficient sub-networks. |

| WAN | A wide area network (WAN) is a network that spans a large geographical area, such as a country or the entire globe. WANs are typically used to connect multiple smaller networks, such as LANs or WLANs, together and can be implemented using various technologies, such as leased lines or satellite links. |

| Web server | A server that is designed to host websites and provide web content and services over the internet. Web servers typically run software, such as Apache or Microsoft IIS, that is responsible for handling requests from clients and serving content in response. |

| WLAN | A wireless local area network (WLAN) is a network that connects devices using wireless technology, such as Wi-Fi. WLANs can be used to provide connectivity within a limited area, such as a home or office, or can be connected to a larger network, such as the internet. |

Modbus terminology

| Term | Definition |

|---|---|

| Address | The location of a register or other data element on a Modbus server. Modbus addresses are typically expressed as 16-bit values, ranging from 0 to 65,535. |

| Client | A device that initiates communication with a Modbus server by sending requests for data or commands. Also known as a master. |

| Command | An instruction or request sent by a Modbus client to a Modbus server. Modbus commands are typically expressed as function codes, which specify the type of operation being requested. |

| Function code | A code that specifies the type of operation being requested in a Modbus command. Modbus function codes range from 0 to 255 and include codes for reading and writing data, diagnostics, and other operations. |

| Latching register | A register that retains its value until it is explicitly overwritten or reset. The specific behavior of latching registers may vary depending on the manufacturer. |

| Master | See "client" |

| Modbus | A communication protocol that is used to exchange data between devices over a variety of communication links, including serial and Ethernet. Modbus is widely used in industrial and building automation systems to enable devices to communicate with each other and exchange data. |

| Non-latching register | A register that does not retain its value after power is removed. The specific behavior of non-latching registers may vary depending on the manufacturer. |

| Register | A location in the memory of a Modbus server that is used to store or retrieve data. Modbus registers are typically 16 bits in size and are addressed using 16-bit values. |

| Server | A device that responds to requests for data or commands from a Modbus client. Also known as a slave. |

| Slave | See "server" |

| Word | A 16-bit value. Modbus registers are typically addressed and accessed as words, rather than individual bytes. |

Introduction

EnergyView is a cloud platform with a user interface (front-end) used to administer NODA's services. The platform consists of several components:

-

Database system (single tenant) based on PostgreSQL.

-

Login system (IdP - identity provider).

-

User interface with a separate view for end users of the product NODA Building, referred to as My pages (Mina sidor).

-

API that enables external systems to interact with NODA.

-

Tools for configuring and administering services and creating reports that visualise data.

-

Integrations for communication with customer installations.

-

Back-end with a software architecture based on microservices that runs in Kubernetes. This document only further describes these services in cases where explaining the relationship to various NODA services is necessary.

The EnergyView platform is of the single tenant type, meaning customers have their own separate databases on separate customer domains. An advantage of this design is that each customer's data is completely separated from other customers' data.

Users

A user can access one or more customer domains. There are two types of users:

-

EnergyView users who have access to EnergyView. These have four different levels of permissions: Basic (see data), Operator (manage settings), Administrator (full access), and API users.

-

My pages users only have access to the My pages/Mina sidor module.

Introduction

EnergyView is a cloud platform with a user interface (front-end) used to administer NODA's services. The platform consists of several components:

-

Database system (single tenant) based on PostgreSQL.

-

Login system (IdP - identity provider).

-

User interface with a separate view for end users of the product NODA Building, referred to as My pages (Mina sidor).

-

API that enables external systems to interact with NODA.

-

Tools for configuring and administering services and creating reports that visualise data.

-

Integrations for communication with customer installations.

-

Back-end with a software architecture based on microservices that runs in Kubernetes. This document only further describes these services in cases where explaining the relationship to various NODA services is necessary.

The EnergyView platform is of the single tenant type, meaning customers have their own separate databases on separate customer domains. An advantage of this design is that each customer's data is completely separated from other customers' data.

Users

A user can access one or more customer domains. There are two types of users:

-

EnergyView users who have access to EnergyView. These have four different levels of permissions: Basic (see data), Operator (manage settings), Administrator (full access), and API users.

-

My pages users only have access to the My pages/Mina sidor module.

Information Model

Each NODA customer has one or more domains on which collected data is stored.

Permission is granted per customer domain, meaning a user can access multiple customer domains. Upon logging in, users with access to numerous customer domains will arrive at a predefined home domain. In the dropdown menu at the top right, users see the domains they have permission for and can switch between domains in the menu (opens in a new window).

This structure means that EnergyView supports customers with one or more customer domains, where each domain has one or more users and one or more customer installations with various services activated.

A customer domain has several collectors, representing objects of a specific type with tags for data. A collector could, for example, mean an indoor sensor, a building, or something else. Collectors can be grouped into groups, which are used in various ways in NODA's services.

erDiagram

CUSTOMER ||..|{ DOMAIN : "owns/has"

CUSTOMER ||..o{ USER-ACCOUNT : "owns/has"

USER-ACCOUNT ||--o{ DOMAIN : "has access to"

DOMAIN ||--o{ COLLECTOR : contains

COLLECTOR {

text name

text description

lable type

representation object

number local-id

UUID global-id

text data-interface-id

}

COLLECTOR ||--o{ TAG : has

TAG {

text namne

text description

text unit

}

GROUP }|--|{ COLLECTOR : contains

Data Structure

Data points are systematised in EnergyView using the concepts of tag, protocol, device, and collector described in the sections below.

Tag

Data points are linked to tags, where a tag corresponds to a measured value or a computed value of a specific sort. Examples of a tag are indoor temperature, power, flow, etc. Measured values are saved in the database on a customer domain via tags.

Protocol

The top level of the structure for data storage on a customer domain in EnergyView is called a protocol. A protocol is a list of tags. Protocols define which tags exist and can be seen as a gross list. If a new tag is to be created, this is done by adding it to an existing or new protocol. Protocols are thus a high-level sorting of tags. They could, for example, be IoT sensors, properties, district heating systems, or similar.

Several objects and properties are used for further systematisation, described under Device and Collector below. In our environment at NODA, for example, we have used a master protocol for tags related to buildings, a protocol for indoor sensors, and a protocol for tags from the weather forecast service we use. Currently, tags are referred to as sensors, but it means the same thing.

Device

Under each protocol, devices that use the protocol are defined. A device has a limited subset of the tags on the protocol to which it belongs. Nothing prevents a device under a protocol from having all the tags on the protocol. Still, devices make it possible to systematise the structure of data. Protocols are the gross list of tags, and devices are net lists of tags. Examples of what devices can correspond to are meters, sensors, control systems, etc.

Collector

A collector is a node representing something which communicates data points with NODA, for example, a district heating substation in a multi-dwelling building, a sensor in an office, or something else. Several properties declare a collector:

- Name: Free text.

- Description: Free text.

- Device (see Device above): a collector is a device.

- Object representation: A label that describes what the collector represents, e.g., Residential building, Indoor climate sensor, Heating circuit, Network station, etc.

- Tags: The collector has access to the Device's tags, and it is possible to choose which tags should be activated on the collector.

- Identifiers created by the system:

- Local identifier: A node ID, which is a serial number for the collector on the customer domain.

- Global unique identifier: A UUID, which can be used to identify the collector via communication between different systems.

- Data interface identifier: This is an ID the user can set themselves and is used for matching when an ID comes from an external system. It is thus an ID that an external system has set, for example, a serial number on a sensor or a MAC address.

Sub-collectors

It is possible to define affiliations between collectors according to a parent-child principle. That is, a collector can be the child of another collector. For example, room sensors can be sub-collectors to a collector representing a building.

Groups

A group consists of collectors. A collector can belong to several groups. Groups are used to describe affiliation for collectors.

API

The EnergyView API comprises two distinct interfaces, namely APIv1 and APIv2. Both interfaces are currently maintained and undergo changes while ensuring backward compatibility.

APIv1

This interface, though older, remains in active use and was initially developed to fulfill our internal requirements. It primarily serves as a representation of the underlying structure of the EnergyView database.

The documentation for APIv1 is publicly accessible and can be located here.

APIv2

Introduced as a newer interface, APIv2 does not diminish the utility of the older APIv1. Its inception was a result of the development of our standalone data store solution, NODA Self-host, in 2021.

To facilitate seamless interoperability between EnergyView and the Self-host system, a compatibility interface was required. Consequently, most, though not all, of the Self-host API functionality was implemented in EnergyView.

The documentation for APIv2 is publicly available and can be found here.

Examples

Understanding the API documentation can be challenging without proper context. To mitigate this, we have created a website featuring examples to assist you. This resource, known as NODA by Example, aims to provide clarity and practical demonstrations.

Collector/Node

A collector is a node representing something which communicates data points with NODA, for example, a district heating substation in a multi-dwelling building, a sensor in an office, or something else. Several properties declare a collector:

-

Name: Free text.

-

Description: Free text.

-

Device (see Device above): a collector is a device.

-

Object representation: A label that describes what the collector represents, e.g., Residential building, Indoor climate sensor, Heating circuit, Network station, etc.

-

Tags: The collector has access to the Device's tags, and it is possible to choose which tags should be activated on the collector.

-

Identifiers created by the system:

-

Local identifier: A node ID, which is a serial number for the collector on the customer domain.

-

Global unique identifier: A UUID, which can be used to identify the collector via communication between different systems.

-

-

Data interface identifier: This is an ID the user can set themselves and is used for matching when an ID comes from an external system. It is thus an ID that an external system has set, for example, a serial number on a sensor or a MAC address.

Error codes and explanations

| Value | Description | Possible Cause |

|---|---|---|

| 0 | No error | No error |

Collector (Node) States Example

A Collector (Node) can have one of several different states. The system declare these states on a Device level. States are used to indicate the status of the Collector and are most often automatically managed by a Program. Still, some state transitions may require manual intervention.

%%{

init: {

'theme': 'base',

'themeVariables': {

'fontFamily': 'Atkinson Hyperlegible',

'primaryColor': '#d53169',

'primaryTextColor': '#fff',

'primaryBorderColor': '#763454',

'lineColor': '#111',

'secondaryColor': '#fca034',

'tertiaryColor': '#4582ec'

}

}

}%%

stateDiagram-v2

[*] --> PreInstallation

PreInstallation --> Deployed

Deployed --> InUse

InUse --> Inactive

InUse --> Faulty

InUse --> Decommissioned

Inactive --> InUse

Inactive --> Faulty

Inactive --> Maintenance

Faulty --> Maintenance

Faulty --> Decommissioned

Maintenance --> InUse

Decommissioned --> [*]

Table description of the states:

| State | Description |

|---|---|

| PreInstallation | The Collector has been created but has yet to be deployed. |

| Deployed | The Collector has been configured and deployed but is not yet used. Data flows in both directions. |

| InUse | The Collector is in use. Any service bound to the Collector is running. |

| Inactive | The Collector is in use but cannot perform its task (service). |

| Faulty | The Collector is in use but has encountered a fault. Transition to Maintenance is required by manual intervention. |

| Maintenance | The Collector is in use but is in maintenance mode. |

| Decommissioned | The Collector is no longer in use. |

State Flow

The above is an example of a typical state flow for a deployed Collector (Node). These states are just an example of a typical deployment, as the conditions are not fixed and can be modified per Device for each Domain.

A purpose-built Program declared in the Program Manager manages the different state transitions. It is thus easy to add new states and transition between states based on the requirements.

If a Collector (Node) is in a Faulty state, additional inquires can be made to determine the cause of the fault. The error timeseries on a Collector (Node) can be used to determine the cause of the fault. The value maps into the Errors table.

How To

Create and Deploy the Building Service via APIv1

This example shows creating and deploying a service via the EnergyView API version 1.

For details about the API, see the online API documentation.

Outline

- Create a Control Node

- Create several Climate Sensor Nodes

- Deply the service on the Control Node

- Update the service

- Summary

Step 0: Prerequisites

You are going to need to have an API key to be able to interact with the API. You can create an API key in the EnergyView web interface if you have enough privileges. You need to contact your system administrator if you do not have enough privileges.

Each request is performed against https://customer.noda.se/{domain}/api/v1/... where {domain} is the domain name of your EnergyView instance. A customer may have several domains, and a separate database manages each domain. This item is sometimes also referred to as "site".

Step 1: Create a Control Node

The first step is to create a Control Node. This is the Node that will act as a representation of a single heating or cooling system. It will contain all the settings and data required for the algorithms to work.

The Control Node is created by sending a POST request to the /{domain}/api/v1/nodes endpoint.

The format of the request body is JSON, and the following is an example of a valid request body:

{

"uuid": "12345678-1234-1234-1234-123456789012",

"name": "My Control Node",

"designation": "building",

"description": "My Control Node for my building",

"dataif": "optional string used as an identifier",

"tags": [

"operational_state",

"outdoortemp",

"outdoortemp_fake",

"outdoortemp_offset",

"returntemp_sec",

"supplytemp_sec",

"supplytemp_sec_controller_setvalue",

"supplytemp_sec_offset",

"meter_effect",

"meter_heatenergy",

"meter_primreturntemp",

"meter_primsupplytemp",

"meter_volume",

"meter_volumeflow",

],

"device": "ControlNode",

"state": "pre-installation"

}

Table of the fields in the request body:

| Field | Description |

|---|---|

| uuid | (optional) The requested UUID of the Node. If not specified, a random UUID will be generated. This can be used to assign a specific UUID to a Node. |

| name | The name of the Node. |

| designation | The designation of the Node. If the Node is a building, a heating system, an indoor climate sensor, etc. |

| description | A description of the Node. |

| dataif | An optional string that can be used as a secondary way to identify the Node. |

| tags | A list of tags that can be used to identify the Node. This is the complete list of sensors we want to enable on the Node. The system manages a fixed list of tags for different devices. |

| device | The device type of the Node. |

| state | The state of the Node. |

The response will be a 201 Created, and the response body will contain the created Node's serial ID and UUID.

{

"id": 123,

"uuid": "12345678-1234-1234-1234-123456789012"

}

Keep the serial ID or UUID of the created Node, as they will be used in the next step.

Step 2: Create Climate Sensor Nodes

The next step is to create Climate Sensor Nodes. These are the nodes that will act as a representation of a single indoor climate sensor. Each Climate Sensor Node will be associated with a Control Node.

The Climate Sensor Nodes are created individually by sending a POST request to the /{domain}/api/v1/nodes endpoint.

The format of the request body is JSON, and the following is an example of a valid request body:

{

"uuid": "cafe1234-cafe-cafe-cafe-cafe12345678",

"name": "My Climate Sensor Node #1",

"designation": "sensor/indoor",

"description": "One of several climate sensors",

"dataif": "optional string used as an identifier",

"tags": [

"indoortemp"

],

"parent": "12345678-1234-1234-1234-123456789012",

"device": "Generic Indoor Sensor",

"state": "pre-installation"

}

The description of the fields in the request body is the same as for the Control Node. With one exception, the parent is a required field that specifies the serial ID or UUID of the Control Node that the Climate Sensor Node should be associated with.

The response will be a 201 Created, and the response body will contain the created Node's serial ID and UUID.

{

"id": 124,

"uuid": "cafe1234-cafe-cafe-cafe-cafe12345678"

}

Repeat the process for each Climate Sensor Node you want to create.

Step 3: Deploy the Service

The last step is to deploy the service on the Control Node. This will enable the algorithms to start running.

The service is deployed by sending a POST request to the /{domain}/api/v1/nodes/{id}/provision endpoint, where {id} is the serial ID of the Control Node.

The format of the request body is JSON, and the following is an example of a valid request body:

{

"active": true,

"balance_temperature": 17,

"idt_wanted": 21,

"idt_min": 17

}

Table of the fields in the request body:

| Field | Description |

|---|---|

| active | Whether the service should be active or not. |

| balance_temperature | The balance temperature of the system. This is typically the outdoor temperature after which the pump is turned off. |

| idt_wanted | The average indoor temperature wanted for the cluster of climate sensors. |

| idt_min | The minimum allowed indoor temperature on any indoor climate sensor. |

The response will be a 204 No Content, and the response body will be empty.

Step 4: Update the Service

A running service can be updated by repeating the same process as in step 3. The service will be updated with the new settings.

Set the active field to false to stop the service.

Summary

You have created a Control Node and Climate Sensor Nodes and deployed the service on the Control Node. The service will start running, and you can send data to the Climate Sensor Nodes via the time series API.

For details about the time series API, look at the API documentation.

Get the current status of a service via APIv1

TODO

Introduction

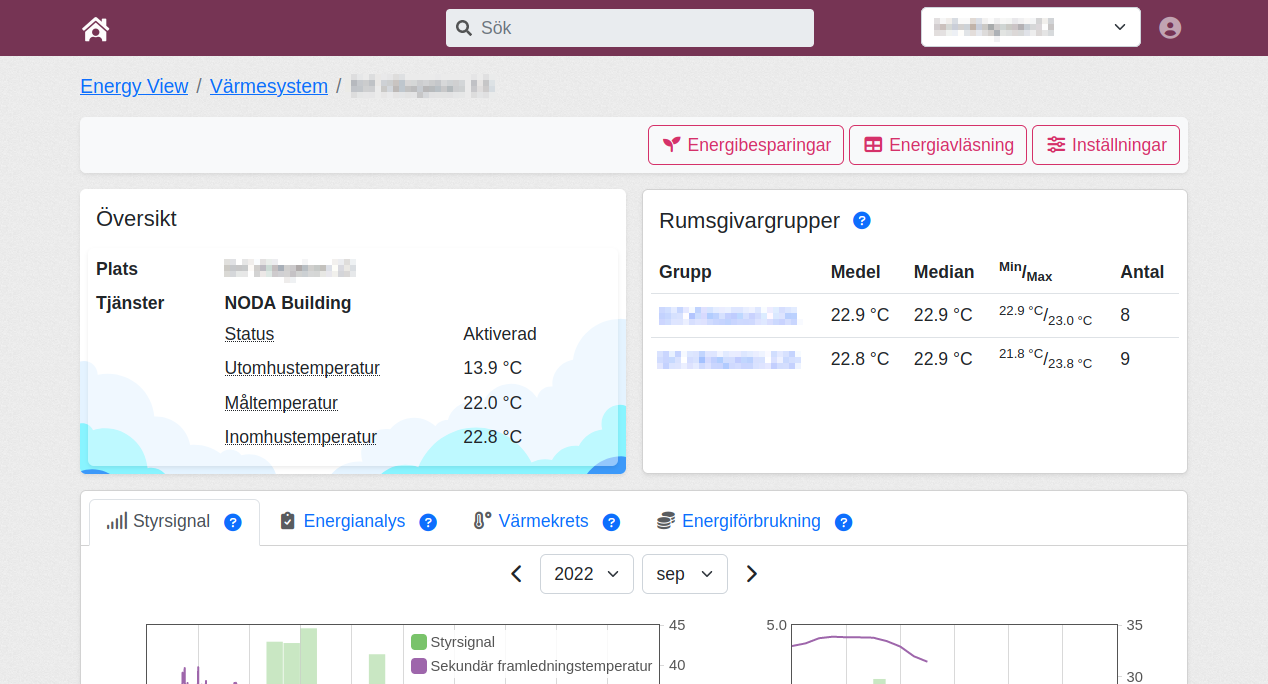

My Pages is a specific user portal for the NODA Building product, which helps property owners save energy and costs, achieve a more consistent indoor temperature, and enable the monitoring of the property's heat usage and indoor comfort over time.

The service is a cloud-based software that relies on data collection from the property and its substation to NODA's server. NODA uses the data to control heating more efficiently and to visualise the property's heat usage. Energy savings from the service are achieved by adjusting the heating of the radiator circuit inside the building to the actual needs of the property instead of just the outdoor temperature (the latter is the typical way to control heating in properties).

The system learns how the property uses energy by using room sensors for indoor temperature. By setting an indoor target temperature for the property, the service can control the heating towards this, thus avoiding unnecessary heating and maintaining a steady indoor temperature. The system also relies on weather forecasts to adjust the energy use to what is needed.

The user portal provides information based on the data collected from connected properties. It allows for monitoring indoor temperatures, viewing how much the service controls to optimise heating, observing energy use, and energy savings.

Introduction

My Pages is a specific user portal for the NODA Building product, which helps property owners save energy and costs, achieve a more consistent indoor temperature, and enable the monitoring of the property's heat usage and indoor comfort over time.

The service is a cloud-based software that relies on data collection from the property and its substation to NODA's server. NODA uses the data to control heating more efficiently and to visualise the property's heat usage. Energy savings from the service are achieved by adjusting the heating of the radiator circuit inside the building to the actual needs of the property instead of just the outdoor temperature (the latter is the typical way to control heating in properties).

The system learns how the property uses energy by using room sensors for indoor temperature. By setting an indoor target temperature for the property, the service can control the heating towards this, thus avoiding unnecessary heating and maintaining a steady indoor temperature. The system also relies on weather forecasts to adjust the energy use to what is needed.

The user portal provides information based on the data collected from connected properties. It allows for monitoring indoor temperatures, viewing how much the service controls to optimise heating, observing energy use, and energy savings.

Introduction

Introduction

API

Infrastructure introduction

The infrastructure required to run the NODA system is reasonably complex. It is no surprise that a complex system carries an inherently higher risk of exposure to attacks.

At the forefront of every design decision, NODA strives to mitigate the risk of such attacks.

Reliable, secure and encrypted communication channels are vital to achieving a secure environment.

But it's not the only item of importance.

Who has access, when they have access and why they have access are just as essential to prevent intrusion.

Devices in the field must never expose any ports to the internet. Instead, NODA solves the two-way communication by establishing a secure communication channel over MQTT to a managed service where each device has its own access rules.

Suppose the private certificate on a device, for whatever reason, is highjacked. Then, the device can easily be black-listed, and the certificate revoked to prevent further access.

Infrastructure introduction

The infrastructure required to run the NODA system is reasonably complex. It is no surprise that a complex system carries an inherently higher risk of exposure to attacks.

At the forefront of every design decision, NODA strives to mitigate the risk of such attacks.

Reliable, secure and encrypted communication channels are vital to achieving a secure environment.

But it's not the only item of importance.

Who has access, when they have access and why they have access are just as essential to prevent intrusion.

Devices in the field must never expose any ports to the internet. Instead, NODA solves the two-way communication by establishing a secure communication channel over MQTT to a managed service where each device has its own access rules.

Suppose the private certificate on a device, for whatever reason, is highjacked. Then, the device can easily be black-listed, and the certificate revoked to prevent further access.

Design in broad brush strokes

NODA aims to control energy equipment situated in the field. These devices are often located in the basement of buildings or inside smaller sheds in the vicinity.

By gathering vital data from these devices and crunching the numbers with machine learning algorithms, NODA achieves energy savings on a building level and also solves far more complex city-wide problems.

NODA provides equipment at the customer's site to communicate with many existing energy controllers. Often without the need to replace any existing hardware.

graph LR

subgraph CustomerSite["Customer Site"]

Energy_Controller["Energy Controller"]

NODA_Equipment["NODA Equipment"]

end

subgraph AnotherCustomerSite["Customer Site"]

SCADASystem["SCADA System"]

APIIntegration["NODA API Integration"]

end

subgraph NODA["NODA"]

subgraph Kubernetes["Kubernetes"]

APIServer["APIServer"]

Computations["Machine Learning"]

MQTTBackend["MQTT Backend"]

UI["User Interface"]

end

MQTTBridge["MQTT Bridge"]

Database[("Database")]

end

Person["User 🧑"]

APIIntegration --> SCADASystem

APIIntegration -->|"Internet 🔒"| APIServer

NODA_Equipment --> Energy_Controller

NODA_Equipment -->|"Internet 🔒"| MQTTBridge

APIServer --> Database

MQTTBridge <-->|"🔒"| MQTTBackend

MQTTBackend --> Database

Computations --> Database

UI --> Database

Person --> UI

On the server-side, NODA manages all of the ingress data, performs computations and solves optimization problems using both multi agent systems and machine learning.

Finally, the resulting control action signal is sent back to the controller over the internet.

Most of the data from these computations are then organized and presented so that it's practical and helps the customer in their daily work.

Development Process at NODA

At NODA, our roots in Software Engineering and Computer Science shape our approach to software development. As a company committed to excellence, we ensure that our development processes reflect our dedication to quality, collaboration, and innovation.

Collaboration and Transparency

We believe that transparency and collaboration are key to successful project delivery. Our development process is designed to be open and inclusive, ensuring that all stakeholders are kept informed and involved. By employing an iterative, community-like process, we maintain flexibility and adaptability, ensuring that our solutions meet the evolving landscape.

Embracing Free and Open Source Software

As a small company, we deeply appreciate the contributions of the Free Software and Open Source communities. While it is not always possible for us to contribute back directly, we encourage our employees to participate in and contribute to open source projects whenever possible. This not only helps the community but also enhances our team's skills and knowledge.

Development Process

Planning

Planning is the first step required for any development process. Given that most projects are based on a delivery date, we start with that and work backwards to ensure a comprehensive plan. This involves establishing:

-

Maintenance Period: Determining the duration for which the software will be maintained post-deployment.

-

Project Deadline: Setting the final delivery date for the project.

-

Testing Period: Allocating time for comprehensive testing to ensure the solution meets all requirements and quality standards.

-

Development Period: Scheduling the necessary time for the actual development work, including coding and initial testing.

-

Requirement Analysis Period: Defining the time needed for gathering, analyzing, and finalizing project requirements.

-

Resource Allocation: Identifying and assigning the necessary resources for both the development and maintenance phases.

For projects or solutions with ongoing development and evolving requirements, each addition of new features should be treated as a separate small or large project depending on the scope.

While this process may resemble the traditional Waterfall methodology, and in many respects it functions similarly, it is designed to ensure thoroughness before progressing to the next stage. This approach minimizes the risk of investing time and resources in work that may later prove unnecessary. However, unlike the rigid structure of Waterfall, our process is flexible and encourages back-stepping when necessary. This adaptability allows us to revisit and revise previous stages to ensure we are always working on the right tasks and meeting the project’s evolving needs.

Call it what you will; we simply don't put a label on it.

Requirement Analysis

At the outset, we focus on thoroughly understanding the needs and defining the project requirements. This involves:

-

Conducting requirement elicitation meetings with key personnel and stakeholders.

-

Performing research to determine the feasibility of the requirements.

-

Developing a project-specific Requirement Specification.

-

Engaging in negotiations to determine which requirements can be addressed and which cannot, often due to time constraints and resource availability.

The initial phase of requirement analysis concludes once all relevant parties have agreed on the specifications and the interpretation of each requirement.

Prototyping

Certain requirements may involve concepts or dependencies that fall outside the immediate expertise of the development team. To accurately assess the feasibility of these requirements, prototyping becomes essential. Prototyping allows us to explore, experiment, and gain the necessary knowledge to make informed decisions.

For example:

-

Integrating New Technologies: When a requirement involves using a new or unfamiliar technology, we create a prototype to test its compatibility and performance within our solution.

-

Complex User Interfaces: For most user interface designs, we develop prototypes to validate usability, functionality, and user experience.

-

System Interoperability: When the project requires integration with external systems or APIs, we prototype these connections to ensure smooth and reliable interactions.

-

Performance Testing: Prototypes can be used to test the system's performance under various conditions, identifying potential bottlenecks and optimization opportunities.

Prototyping helps us mitigate risks, validate assumptions, and refine our approach before full-scale development begins, ensuring a more efficient and effective development process.

Design

Based on the requirements outlined in the Requirement Specification, we design the system architecture, user interfaces, and other key components with security as a primary focus.

During the design phase, new requirements or adjustments to existing requirements may arise. As a result, we must remain flexible and revisit previous steps in the process to accommodate these necessary changes, often requiring a new iteration of Requirement Analysis.

Throughout the design phase, we will often produce:

-

System Architecture Diagrams: Detailed representations of the system's structure, including modules, data flow, and integration points.

-

User Interface Mockups: Visual prototypes of the user interfaces to ensure alignment with user experience goals and client expectations.

-

Database Schemas: Structured plans for data storage, ensuring efficient data management and retrieval.

-

Security Models: Plans addressing security measures to protect data integrity and privacy.

-

Technical Specifications: Documentation outlining the functionalities and interactions of each component, providing a clear blueprint for the development team.

Certainly! Here is the adjusted and extended version of the Testing chapter:

Testing

The concept of testing should precede the implementation phase. Even though there is nothing to test before code is written, sufficient information should be available for developers to prioritize testing from the outset. This approach shifts the traditional mindset of implementing first and testing later to a more proactive strategy of considering how to test functionality before implementing it, ensuring that the implementation is inherently testable.

Testing is conducted throughout the entire development phase and extends beyond it until we are satisfied with the quality assurance.

Artifacts from testing often include:

-

Unit Tests: Comprehensive tests for individual components, with a coverage target where less than 90% is unacceptable. These tests ensure each part of the codebase functions as intended.

-

Integration Tests: Tests to ensure that different modules and components work together seamlessly.

-

System Tests: End-to-end testing of the complete system to verify that it meets all specified requirements.

-

Performance Tests: Assessments to ensure the system performs well under various conditions and loads.

Development

During the development phase, code is written with testability and security as primary core pillars. Features are developed in separate branches, and once a feature is completed and passes all its tests, a merge request is created. A reviewer then examines the merge request, and if adjustments are necessary, the developer must make the modifications before the updated merge request is reviewed again. Once accepted, the code is merged into the main codebase. Each change is tracked using a versioning system (Git), allowing any state of the source code to be investigated.

If developers encounter issues that require changes to the Design or necessitate negotiations about the Requirements, these issues should be promptly raised with the responsible parties for each phase to find a solution.

Freeze

Once all features, or a limited set of features due to time constraints, have been merged into the main branch, a code freeze is implemented. During a freeze, no new features may be merged, and the current state of the main branch is assigned a tag. Development can continue in other branches, but the main branch is off-limits to ensure stability and focus on finalizing the current release. This period is used for final testing, bug fixes, and preparation for the release.

Only critical bugs may result in a slight thaw, where patches are merged to address these issues. Otherwise, the freeze remains in effect, ensuring the integrity and stability of the main branch until the release is complete.

During this time, the deployment team is notified about the upcoming release so they can schedule and prepare for the necessary work to deploy the solution into production.

Staging

Before deploying the solution, it undergoes testing in a staging environment. During this phase, a period of soak testing is conducted, where the system is used as if it were in a production environment. The duration of the soak testing period varies depending on the specific circumstances, and it is up to the testing team to determine the appropriate length of time required on a case by case basis.

Deployment

Once the testing team approves the contribution, the tagged release is assigned an appropriate version number and a build is pushed to the registry in the production environment. During the scheduled maintenance window, the deployment team pushes the update to the production system and monitors it for any unusual behavior for the next few hours. If any issues arise, a rollback to the previous version is performed.

Maintenance

Once the deployment team completes their work, the maintenance period begins. During this phase, automated logging mechanisms are in place to detect and report any unexpected behavior. These systems continuously monitor the application, ensuring that any issues are promptly identified and addressed.

Additionally, regular updates and patches are applied to maintain the system’s security and performance.

Software Lifecycle

We follow a structured process to ensure smooth software deployment. This process guides us through code commits, testing, deployment, and potential rollback, ensuring reliability and consistency throughout.

graph TD;

ReportIssue[Report Issue]

Start([Start]) --> A[Planning]

A --> B[Requirement Analysis]

B --> C[Prototyping]

C --> D[Design]

D --> E[Development]

E --> F{Run Tests}

F -->|Pass| G[Code Freeze]

G --> Staging[Staging]

Staging --> I[Tag Release]

Staging -->|Major Issue|ReportIssue

I --> J[Manual Building\nof Container]

J --> K{Deploy to\nProduction}

K -->|Success| L([Success])

K -->|Fail| M[Revert to Previous\nVersion]

M --> ReportIssue --> E

F -->|Fail|E

F -->|Major Issue|D

D -->|Major Issue|B

Security of the infrastructure

%%{init: {'theme': 'base', 'themeVariables': { 'fontSize': '60px' }}}%%

graph TD

Vest["🔒 🦺 🔑"]

Accounts

-

Never give personnel more access than strictly necessary to do their work.

-

Whenever possible, use automatic termination of accounts after a specific date or period.

Installation site

-

One should install hardware such as Modbus Gateway behind at least a locked door.

-

One must report missing hardware and its certificates revoked ASAP.

-

Equipment must be password protected with a unique random password.

-

Equipment must connect over an encrypted channel.

-

Equipment must never expose itself on the public internet.

-

Equipment must continuously be updated with security patches.

Office

-

Employees at NODA are required to use Bitwarden for password management.

-

TOTP is enforced whenever possible. For the most important objects, U2F security keys (from Yubico) are used.

-

Employees' workstations/laptops are full-disk encrypted.

-

Employees' workstations/laptops must be updated with new security patches at a regular interval.

-

WiFi passwords to the office network are never shared with visitors or friends.

Servers

-

Software that exposes an interface to another system must always require authentication, even if the system exposes an interface in a "secure" environment.

-

Access to the server system is only allowed through an SSH bastion using certificate authentication. Only the DevOps team has access to this gateway.

-

One must never expose the Kubernetes API to the internet outside a maintenance window. During these windows, only a handful of selected IP addresses are allowed to communicate with the API endpoint.

-

Machines, Container and Software packages must be tracked for updated of security patches.

Code

-

Code in repositories is continuously scanned for new security vulnerabilities.

-

Whenever an issue is found, the code is patched, verified and deployed within the next available maintenance window.

-

Employees are only given access to a project they are working on.

-

Code is written with security in mind.

-

As few dependencies on external systems as possible.

-

Known libraries shall ONLY ever manage cryptography. Never implement a crypto-solution by yourself.

-

Having test cases for most of the code is key to having a stable code base.

-

Transparency

Infrastructure

-

The NODA "Cloud" is hosted on AWS (Amazon Web Services) in the eu-north-1 region.

-

NODA uses DigitalOcean and Vultr for development and testing.

-

NODA uses Google Workspace.

-

NODA relies on FOSS (Free and Open Source) projects as part of the platform.

-

The platform is written in house, and is of our own design.

Work environment

-

NODA allows its employees to work from home.

-

Employees use Linux, FreeBSD, Windows and macOS in their workstations/laptops.

Software

-

NODA relies on several Open Source projects (to mention a few);

-

The software for the Modbus Gateway Addon is written using Arduino.

Open Source software licenses

NODA uses FOSS software with the following licenses;

- Apache License, Version 2.0

- BSD License 2, BSD License 3

- Eclipse Public License version 2.0

- GPLv2

- GPLv3

- LGPLv3

- MIT License

- Mozilla Public License 2.0 (MPL 2.0)

- Python License, Version 2

- PHP License, version 3.01

- Zope Public License 2.1

3rd-party solutions

Examples

Modbus Gateway Installation

A NODA Modbus Gateway can connect to any Modbus TCP or RTU capable energy controller. The NODA Modbus Gateway then reads and writes values to the energy controller using the Modbus protocol.

Installation complexity varies depending on the installation scenario;

- Freely programmable controller: Configurable Modbus layout and programmable logic.

- Application-specific controller: Static Modbus layout with only parameterise logic.

A freely programmable controller has to be configured to expose the required values. An application-specific controller seldom has the option to change the Modbus layout. Nor is it often possible to handle a failsafe mode directly in the controller using software logic.

An application-specific controller may contain this feature if the specific feature was part of the requirements when the controller was designed.

To solve this problem, NODA has developed the NODA Modbus Gateway Addon. A device that sits between the energy controller and the NODA Modbus Gateway and provides the missing logic required to handle situations when a connection to the internet fails for several hours or days.

graph TD

subgraph clusterAWSIoT["AWS IoT"]

IoT_Server["IoT Server"]

end

subgraph clusterSiteA["Customer Site"]

Modbus_Gateway["Modbus Gateway"]

Modbus_Gateway_Addon["Modbus Gateway Addon\n(optional)"]

Energy_Controller["Energy Controller"]

end

Modbus_Gateway -->| | Modbus_Gateway_Addon

Modbus_Gateway_Addon -->| | Energy_Controller

Modbus_Gateway -->|"🔒"| IoT_Server

The NODA Modbus Gateway connect to the secure endpoint on AWS IoT. Data is then forwarded to the NODA system and handled by various processes. The system crunches the numbers and sends control signals back the controller via AWS IoT and the NODA Modbus Gateway.

Finally, a customer connects to the EnergyView (or My Pages) system to browse the data at their heart's content.

graph LR

subgraph clusterNodaPrivate["Noda Private"]

DBMS[("DBMS")]

Mosquitto["Mosquitto"]

end

subgraph clusterNodaPublic["Noda Public"]

EnergyView["EnergyView"]

Mosquitto["Mosquitto"]

end

subgraph clusterAWSIoT["AWS IoT"]

IoT_Server["IoT Server"]

end

subgraph clusterSiteA["Customer Site"]

Modbus_Gateway["Modbus Gateway"]

end

Mosquitto -->| | DBMS

EnergyView -->| | DBMS

IoT_Server -->|"🔒"| Mosquitto

Modbus_Gateway -->|"🔒"| IoT_Server

Customer["💻 Customer"]

Customer -->|"🔒"| EnergyView

Indoor Sensors Installation

There are several ways to get indoor sensor data into the NODA system.

The most common way is for equipment in the field to send data to NODA. This can be either via Wireless M-Bus gateways or via MQTT or HTTP from a gateway connected to a LoRa network.

These devices are often provisioned once and usually work for several years without intervention.

graph LR

subgraph clusterNodaPrivate["Noda Private"]

DBMS[("DBMS")]

end

subgraph clusterNodaPublic["Noda Public"]

EnergyView["EnergyView"] -->| | DBMS

W_MBus["W-MBus"] -->| | DBMS

end

subgraph clusterSite["Customer Site"]

Indoor_Sensors["🌡️ Indoor Sensors"]

Indoor_Sensors -->|"🔒"| W_MBus

end

Customer["💻 Customer"]

Customer -->|"🔒"| EnergyView

Typical logging intervals are between 5 and 15 minutes, depending on expected lifespan, technology and so forth. Once the data has landed in the NODA system it can be viewed by customers using either EnergyView or My Pages.

3rd Party Integration Installation

While not very common, NODA allows for customer specific intergrations. This is often solved by using the NODA EnergyView API or the NODA Self-host API.

graph LR

subgraph clusterNodaPrivate["Noda Private"]

DBMS[("DBMS")]

end

subgraph clusterNodaPublic["Noda Public"]

EnergyView["EnergyView"] -->| | DBMS

end

subgraph clusterSiteC["Customer Site"]

Third_Party_Solution["3rd party solution"] -->|"🔒"| EnergyView

end

Customer["💻 Customer"]

Customer -->|"🔒"| EnergyView

IEC Installation

NOTICE: This solution reaches end of life (EOL) on the 31st of December 2022.

The NODA IEC is a solution built in-house by NODA. It sits between an outdoor sensor (RTD) and the energy controller. The IEC measures the resistance of the outdoor sensors, converts it to a temperature, applies an offset (or not) and converts the new temperature back to a resistance value for the controller.

This solution has both benefits and drawbacks. Using this method, one can not control specific circuits in a building unless there is one controller for each circuit. In addition, everything affected by the outdoor temperature will be affected by an offset.

However, it's a simple concept and works well if used in the right circumstances.

graph LR

subgraph clusterNodaPrivate["Noda Private"]

DBMS[("DBMS")]

end

subgraph clusterNodaPublic["Noda Public"]

EnergyView["EnergyView"]

IEC_Sync["IEC Sync"]

end

subgraph clusterSiteA["Customer Site"]

IEC["IEC"]

end

EnergyView -->| | DBMS

IEC_Sync -->| | DBMS

IEC -->|"🔒"| IEC_Sync

Customer["💻 Customer"]

Customer -->|"🔒"| EnergyView

Since the IEC cannot query an energy controller for measured values, these are collected by installing surface-mounted 1-wire temperature sensors on the essential circuits.

Important usage and safety information

The following safety precautions must be observed during all phases of the operation, usage, service or repair of any NODA product.

Users of the product are advised to convey the following safety information to users and operating personnel and to incorporate these guidelines into all manuals supplied with the product. Failure to comply with these precautions violates safety standards of design, manufacture and intended use of the product.

NODA Intelligent Systems AB assumes no liability for customer’s failure to comply with these precautions.

The products are developed for indoor use only, unless clearly stated otherwize.

The installation of the product should be performed by a qualified electrician or another professional with the required knowledge. It is important to follow all safety information of this manual when installing the product.

Make sure to read this manual carefully and follow it step by step to ensure a secure usage and to get the most out of your product.

Mobile router introduction

Communication with equipment in the field can be solved using various solutions. Choosing one of these solutions always boils down to weighing functionality vs cost.

Using a customer's existing infrastructure to communicate with the internet is always a problem. Especially so, if the customer is unfamiliar with their own infrastructure.

As a result, NODA decided to go with a mobile router solution. A device which, on its own, connects to the internet via the 4G or 5G mobile network. Then, this mobile router connects to the energy controller (A regulator or similar device) via Modbus over either TCP or RTU.

All of this is secured by exchanging data over an encrypted MQTT connection.

NODA requires this level of interaction with the energy controller to get all required measurement values, along with the ability to modify control parameters. This way, the controller can go about its business doing what it's good at, controlling. Whilst being nudged in the right direction by the analytic processes provided by NODA.

Mobile router introduction

Communication with equipment in the field can be solved using various solutions. Choosing one of these solutions always boils down to weighing functionality vs cost.

Using a customer's existing infrastructure to communicate with the internet is always a problem. Especially so, if the customer is unfamiliar with their own infrastructure.

As a result, NODA decided to go with a mobile router solution. A device which, on its own, connects to the internet via the 4G or 5G mobile network. Then, this mobile router connects to the energy controller (A regulator or similar device) via Modbus over either TCP or RTU.

All of this is secured by exchanging data over an encrypted MQTT connection.

NODA requires this level of interaction with the energy controller to get all required measurement values, along with the ability to modify control parameters. This way, the controller can go about its business doing what it's good at, controlling. Whilst being nudged in the right direction by the analytic processes provided by NODA.

Hardware options

NODA relies on hardware from the manufacturer Teltonika.

The router we use and support are;

The RUT240 is primarily used as a Mobile router for wired ethernet devices, while the RUT950 and RUT955 series are mainly used as Modbus Gateway.

Remote management

An essential function of equipment deployed in the field is accessing these devices securely.

Devices such as routers always require software upgrades or maintenance to fix newly discovered security vulnerabilities.

Often this requires a VPN solution at the customer site. Or that each router connects as a client to a central management system using VPN.

The should be no situations where equipment is directly exposed to the internet. Such a solution is fraught with troubles down the line.

The NODA routers provided by Teltonika solve this problem by providing a secure connection using secured MQTT as a transport layer. The device connects to Teltonikas Remote Management System (RMS), where all devices are accessible and easily managed.

Introduction

NODA Modbus Gateway provides a reliable Modbus TCP master/slave solution where data transmits over a secure MQTT connection.

The Modbus Gateway acts as a Modbus TCP or RTU master/slave. It can communicate with any Modbus TCP slave connected via the LAN interface or act as a Modbus TCP slave. It can also communicate with any Modbus RTU slave connected via an RS-485.

Data is transmitted over the mobile network using a 4G or 5G modem internal to the gateway. The LAN interface or the RS-485 bus is not used to transfer outbound data to NODA. Only the WLAN connection via Wired Ethernet or Mobile Internet can access the internet.

For a list of limitations concerning the installation, see the details in Modbus support.

Introduction

NODA Modbus Gateway provides a reliable Modbus TCP master/slave solution where data transmits over a secure MQTT connection.

The Modbus Gateway acts as a Modbus TCP or RTU master/slave. It can communicate with any Modbus TCP slave connected via the LAN interface or act as a Modbus TCP slave. It can also communicate with any Modbus RTU slave connected via an RS-485.

Data is transmitted over the mobile network using a 4G or 5G modem internal to the gateway. The LAN interface or the RS-485 bus is not used to transfer outbound data to NODA. Only the WLAN connection via Wired Ethernet or Mobile Internet can access the internet.

For a list of limitations concerning the installation, see the details in Modbus support.

Compatibility requirements

For a list of known compatible devices, take a look at Manufacturer templates.

General requirements

A typical installation requires the ability to READ the following tags/values;

- Outdoor temperature

- Primary side flow (supply) temperature

- Primary side return temperature

- Primary side flow (supply) volume

- Primary side volume

- Primary side heat energy

- Primary side heat power

- Secondary side #1 flow temperature

- Secondary side #1 return temperature

- Current secondary side supply temperature

NOTE: If additional secondary side loops exist, they can also be included.

Along with the ability to WRITE the following tags/values;

- Secondary side supply temperature offset

or

- Forced secondary side supply temperature

Whichever depends on the limitations of the Modbus slave and the control system behind it.

NOTE: Specific use cases may require situation-specific solutions. In such a case, don't hesitate to get in touch with NODA for further support.

Components

The NODA Modbus Gateway consists of;

- Teltonika Mobile Router

- Antennas

- Power Supply Unit

- SIM-card (may be omitted)

- Modbus Gateway Addon (required for certain energy controllers)

Teltonika Hardware options

There are two different hardware options available;

RUT950/RUT951

The RUT950 and RUT951 are 4G routers. They come with 3 LAN (Ethernet) ports and 1 WAN (Ethernet) port. This option is well suited for use with freely programmable energy controllers with support for Modbus TCP.

RUT955/RUT956

The RUT955 and RUT956 are 4G routers. They come with 3 LAN (Ethernet) ports and 1 WAN (Ethernet) port; they also have 1 RS-485 port and 1 RS-232 port, along with a few generic I/O ports. This option is well suited for use with freely programmable energy controllers with support for Modbus TCP or Modbus RTU.

Introduction

The NODA Modbus Gateway Addon acts as a tiny external brain-aid for application-specific energy controllers.

Whenever a controller cannot handle the logic required to return to zero from an affected state, this solution is needed to restore the default state on the controller.

For example, if an offset of the supply temperature on the secondary side is 6.5 degrees Celsius and the internet connection goes down. Then, the controller will happily continue with the same 6.5 degrees offset until internet connectivity is restored. For a worst-case scenario, this can take several days.

This addon's sole purpose is to add logic to the energy controller without putting it in the environment of an operating system that is frankly less stable than a microcontroller's.

Components

The hardware we choose, 10 I/O's Digital Module is made by the Spanish company; Boot and Work Corp S.L. (Industrial Shields).

The hardware is built around an ESP32 and supports the Arduino Development Environment.

In the future, we aim to support several off-the-shelf Arduino-compatible products from different manufacturers.

Communication

The NODA Modbus Gateway Addon can communicate with Modbus devices over either Modbus TCP (Ethernet) or Modbus RTU (RS-485).

The solution uses the same protocol over MQTT as the NODA Modbus Gateway.

Modbus TCP

Communication with any Modbus TCP compatible Modbus Slave is possible over any port.

See the Setup section for more details about configuring the Modbus TCP support.

Modbus RTU

The communication protocol does not support specifying an RS-485 target. Instead, only IP targets are supported.

To get around this limitation, the NODA Modbus Gateway Addon assigns special meaning to the IPv4 loopback addresses. The loopback address of 127.1.1.1 is used as a way to forward a request to the RS-485 interface. The TCP port (typically 502) is silently ignored in such a request.

See the Setup section for more details about how to configure the RS-485 support.

Setup of Modbus Gateway Addon

Once powered on, the Addon will either request an IP address via DHCP or use the static IP configured via the user-interface.

When connected to a NODA Modbus Gateway, the Addon device will be assigned the IP 192.168.1.100.

Access the user-interface by entering the following in a web-browser; http://192.168.1.100.

It's is highly recommended to access this page in "incognito" or "private window" to avoid issues with password caching.

Login

The username is admin.

The password is unique for each device and can be requested from NODA.

Configuration

The following parameters can be changed.

Network

- MAC address: The MAC address can be changed here if required.

- Static IP: Assigning a static IP will disable DHCP. An empty field will active DHCP.

- Static DNS: Required if static IP is used.

- Static subnet: Required if static IP is used. On the form

255.255.255.255.

RS485 (for Modbus RTU)

- Baudrate: The speed over the RS-485 network. All devices must use the same speed.

- Mode: e.g. 8N1 or 7E1 etc.

MQTT

- ClientID: Identifier used when connecting to an MQTT broker.

- Host: The IP of the MQTT broker.

- Port: The TCP port of the MQTT broker.

- Username: Optional username used to connect to the MQTT broker.

- Password: Optional password used to connect to the MQTT broker.

Failover

- Communication timeout: The number of seconds without any data over MQTT, after which the device switches to failover state.

- On communication error: A list of instruction to execute when switching to a failover state. These instructions are used to clear any offset and return the energy controller to a clean-state.

Password

- WebUI Password: Used to change the password of the Web-UI.

Modbus support

Since Modbus was designed in the late 1970s to communicate to programmable logic controllers, the number of data types is limited to those understood by PLCs at the time. Therefore, large binary objects are not supported.

No standard way exists for a master device to find the description of a data object, for example, to determine whether a register value represents a temperature between 25 and 98 degrees Celsius.

Therefore the mapping and structure of the data have to be established for successful interoperability, as a client may store values not only in a single register but in several adjacent holding registers.

Limitations in the protocol support

As of this writing, the software used by NODA to achive communication with energy control equipment via Modbus over MQTT, is limited to the support implemented by Teltonika in their equipment.

This limits the available commands to send over Modbus to only Write Single Holding Register (6), Write Multiple Holding Registers (16) and Read Holding Registers (3). There is thus currently no support for reading and writing to coils and reading discrete inputs.

Single holding register data types

- 8 Bit Unsigned Integer (uint8)

- 8 Bit Signed Integer (int8)

- 16 Bit Unsigned Integer (uint16)

- 16 Bit Signed Integer (int16)

- 16 Bit Float (float16)

Multi (2) holding registers data types

- 32 Bit Unsigned Integer (uint32)

- 32 Bit Signed Integer (int32)

- 32 Bit Float (float32)

Both Word and Byte order can be Little- or Big Endian. But the order has to be consistent throughout.

NOTE: While NODA Modbus Gateway supports the above data types, your specific target slave device might not be able to handle them. Please refer to the manual for the slave device for details.

RS-485 limitations

The RS-485 driver can drive a maximum of 32 receivers, provided that the receiver input impedance is 12 k$\Omega$. If receiver impedances are higher, the maximum number of receivers in the network increases. Any combination of receiver types can be connected, provided their parallel impedance does not exceed $Rload > 375 \Omega$.

Solution for complete protocol support

To get around the current limitations in the Teltonika router, NODA implemented a separate solution with the capability of acting as an alternative to the Teltonika software in their router. This solution still requires Teltonika router to access the internet in a secure way. For more details about this solution take a look at the Modbus Gateway Addon

Recommendations

Depending on the usage scenario, limitations or flexibilities in the Modbus TCP slave, the data mapping will vary. Therefore, the following mapping is only the prefered mapping by NODA. As such, it can be changed in agreement with NODA to match the specific situation.

Modbus mapping for a typical building

Word Order: Big Endian

Byte Order: Little Endian

| Order | Value name | Encoding | Amplification | Unit | Direction | Function Code |

|---|---|---|---|---|---|---|

| 1 | Outdoortemp | uint16 | 1/100 | Celcius | Read | 3 |

| 2 | Outdoortemp Offset | uint16 | 1/100 | Kelvin | Write | 6 |

| 3 | Primary Flow (Supply) Temperature | int16 | 1/100 | Celcius | Read | 3 |

| 4 | Primary Return Temperature | int16 | 1/100 | Celcius | Read | 3 |

| 5 | Primary Flow Volume | int16 | 1/10* | l/h* | Read | 3 |

| 6 | Primary Side Volume | int16 | 1/10* | m3* | Read | 3 |

| 7 | Primary Heat Energy | int16 | 1/10* | MWh* | Read | 3 |

| 8 | Primary Heat Power | int16 | 1/10* | kW* | Read | 3 |

| 9 | Secondary Side (#1) Flow | int16 | 1/100 | Celcius | Read | 3 |

| 10 | Secondary Side (#1) Return | int16 | 1/100 | Celcius | Read | 3 |

| 11 | Secondary Side (#2) Flow | int16 | 1/100 | Celcius | Read | 3 |

| 12 | Secondary Side (#2) Return | int16 | 1/100 | Celcius | Read | 3 |

| ... | ... | ... | ... | ... | ... | ... |

| XX | Secondary Side (#n) Flow | int16 | 1/100 | Celcius | Read | 3 |

| XX | Secondary Side (#n) Return | int16 | 1/100 | Celcius | Read | 3 |

* Depends on specific circumstances

The structure outlined in the table can repeat if the Modbus TCP slave interfaces with several regulators and or control points.

NOTE: If additional secondary side circuits exist, they should be included.

NOTE: Holding register numbers are intentionally not outlined as they likely will vary from one Modbus TCP slave to another.

Installation preparation

The NODA Modbus Gateway comes prepared with all necessary certificates to connect to the NODA MQTT network securely.

Modbus TCP

For access to the Modbus TCP slave(s) or acting as a Modbus TCP slave itself. The NODA Modbus Gateway will need either a static or dynamic (DHCP) IP assigned to it in the LAN.

Don't hesitate to contact the network administrator as this information is only known to, and can be handled by, the network administrator. Once an IP number is assigned to the NODA Modbus Gateway, either via static or dynamic assignment, these details should be communicated to NODA, as they are required for device setup on the LAN.

NOTE: If the network administrator requests a MAC address. This address is labelled as LAN MAC on the underside of the NODA Modbus Gateway. If the label is missing or has been damaged, please get in touch with NODA for help.

Modbus RTU

To access Modbus RTU slave(s), the NODA Modbus Gateway will need access to an RS-485 network. Details on how an RS-485 network works are out of scope for this document.

To access Modbus RTU slave(s), the RS-485 bus configuration is required.

Default values are highlighted in bold.

- Baud rate (300, 1200, 2400, 4800, 9600, 19200, 38400, 57600 or 115200)

- Parity bits (none, odd, even)

- Stop bits (1, 2)